New Product Design Capability

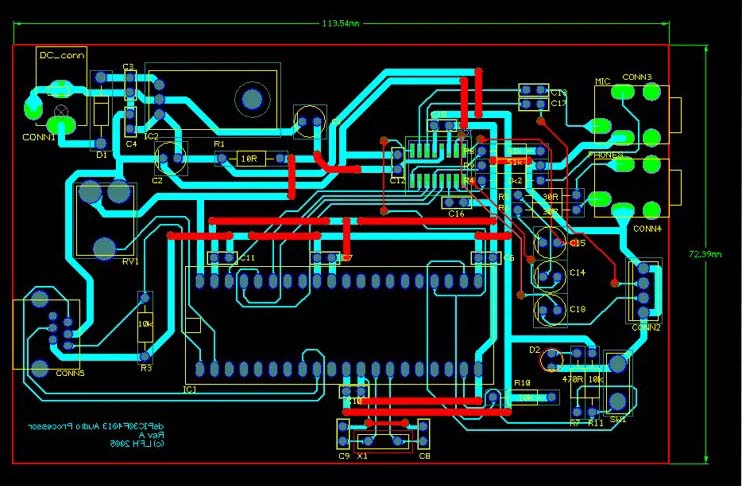

New Product Design Capability Board layout and Design Capability

Board layout and Design Capability Design for manufacturing

Design for manufacturing New Product Introduction

New Product Introduction Manufacturing Engineering

Manufacturing Engineering Research and Development

Research and Development Hardware and software engineering

Hardware and software engineering CAD / CAM

CAD / CAM Complete products

Complete products Surface mount

Surface mount Automated and Manual

Through hole Insertion

Automated and Manual

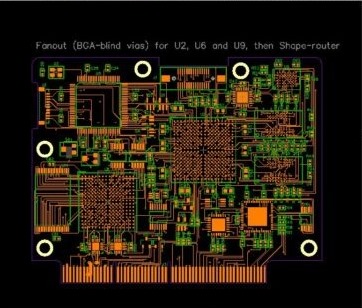

Through hole Insertion BGA

BGA Flex lines

Flex lines Box build and Integration

Box build and Integration In Circuit

In Circuit Functional

Functional Elevated Temperature

Elevated Temperature Mold making and Plastic Injection

Molding

Mold making and Plastic Injection

Molding

Wiring harness

Wiring harness

DEK / MPM – SOLDER PASTE PRINTING

DEK / MPM – SOLDER PASTE PRINTING  FUJI NXT3 – CHIP SHOOTER

FUJI NXT3 – CHIP SHOOTER JUKI / YAMAHA – PICK & PLACE

JUKI / YAMAHA – PICK & PLACE HELLER/VITRONICS – REFLOW OVEN

HELLER/VITRONICS – REFLOW OVEN AKI – AOI

AKI – AOI FIEN FOCUS – X RAY INSPECTION

FIEN FOCUS – X RAY INSPECTION APE INTRUDER – BGA REWORK STATION

APE INTRUDER – BGA REWORK STATION  Z100 – SOLDER PASTE HEIGHT MEASUREMENT

Z100 – SOLDER PASTE HEIGHT MEASUREMENT DE-HUMIDIFIER FOR MSD COMPONENTS

DE-HUMIDIFIER FOR MSD COMPONENTS LAMINAR FLOOR - FOR LENS ASSEMBLY

LAMINAR FLOOR - FOR LENS ASSEMBLY

SEHO / EMS – WAVE SOLDERING

SEHO / EMS – WAVE SOLDERING UNIVERSAL – AUTO INSERTS & SEQUENCERS

UNIVERSAL – AUTO INSERTS & SEQUENCERS ICT – JET

ICT – JET OLAMEF – COMPONENT FORMING

OLAMEF – COMPONENT FORMING DEDICATED TEST BENCHES

DEDICATED TEST BENCHES ELEVATED BURN IN FACILITIES

ELEVATED BURN IN FACILITIES PROTO ASSEMBLY LINES

PROTO ASSEMBLY LINES FUNCTIONAL JIGS

FUNCTIONAL JIGS COMPLETE PRODUCT ASSEMBLY LINE

COMPLETE PRODUCT ASSEMBLY LINE THERMAL CHAMBER

THERMAL CHAMBER VIBRATION TEST SYSTEM

VIBRATION TEST SYSTEM BURNIN LINES FOR THE FINAL PRODUCT

BURNIN LINES FOR THE FINAL PRODUCT DEDICATED TEST EQUIPMENT FOR PRODUCT

TESTING

DEDICATED TEST EQUIPMENT FOR PRODUCT

TESTING

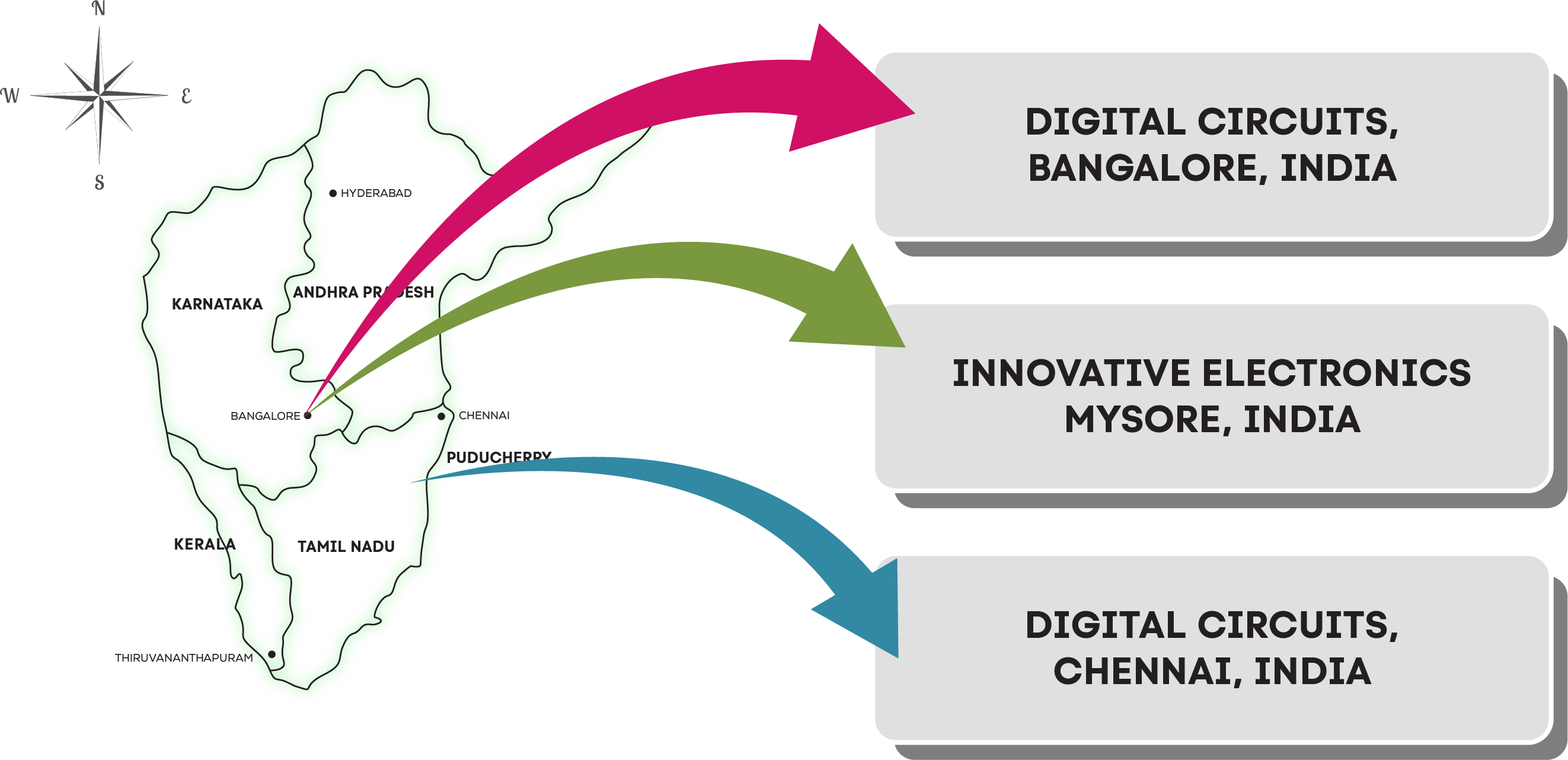

End to End solutionsfrom Design to Delivery

End to End solutionsfrom Design to Delivery

Quality standards as per IPC-610E

Quality standards as per IPC-610E Dedicated team for proto-type

Dedicated team for proto-type Document Control & IP protection

Document Control & IP protection Dedicated member team

Dedicated member team

Design modification / PCB design capability

Design modification / PCB design capability Alternate solution for Obsolete parts

Alternate solution for Obsolete parts Support for EMI/EMC/UL/CE approvals

Support for EMI/EMC/UL/CE approvals“Digital combines global resources with in house capabilitiesto create local success for our Customers”

High Speed Digital, Analog, Mixed & RF

designs

High Speed Digital, Analog, Mixed & RF

designs High layer count boards – 12+ layers

High layer count boards – 12+ layers High density PCBs – > 450 pins/Sq.In

High density PCBs – > 450 pins/Sq.In Fine pitch BGA

Fine pitch BGA Flexible & Rigid flex PCB

Flexible & Rigid flex PCB Design for Manufacturability

Design for Manufacturability Highly skilled PCB / software engineers

Highly skilled PCB / software engineers

Best in Industry rates and competitive

quoting

Best in Industry rates and competitive

quoting